What We Make

We offer a wide range of marine products, including:

- Digital (CAN bus) and analog gauges

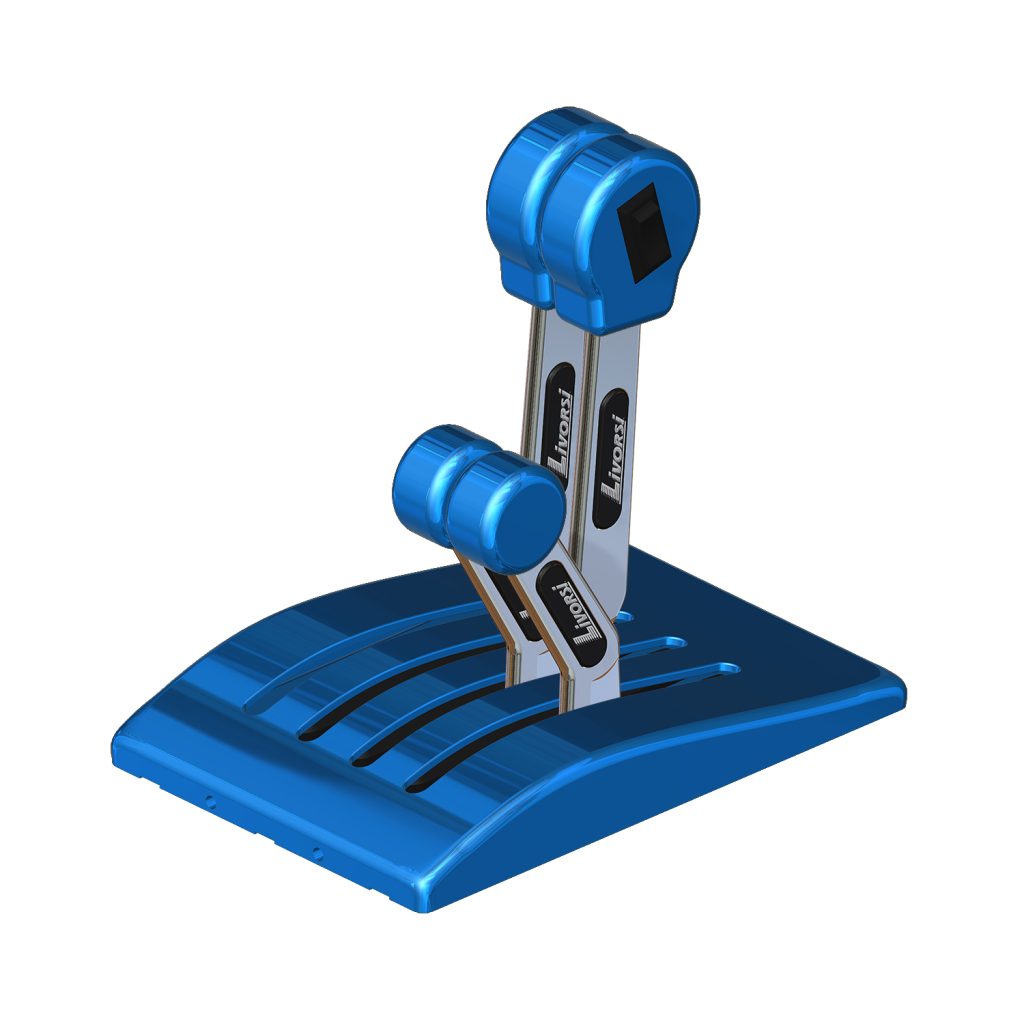

- Mechanical and electronic throttles

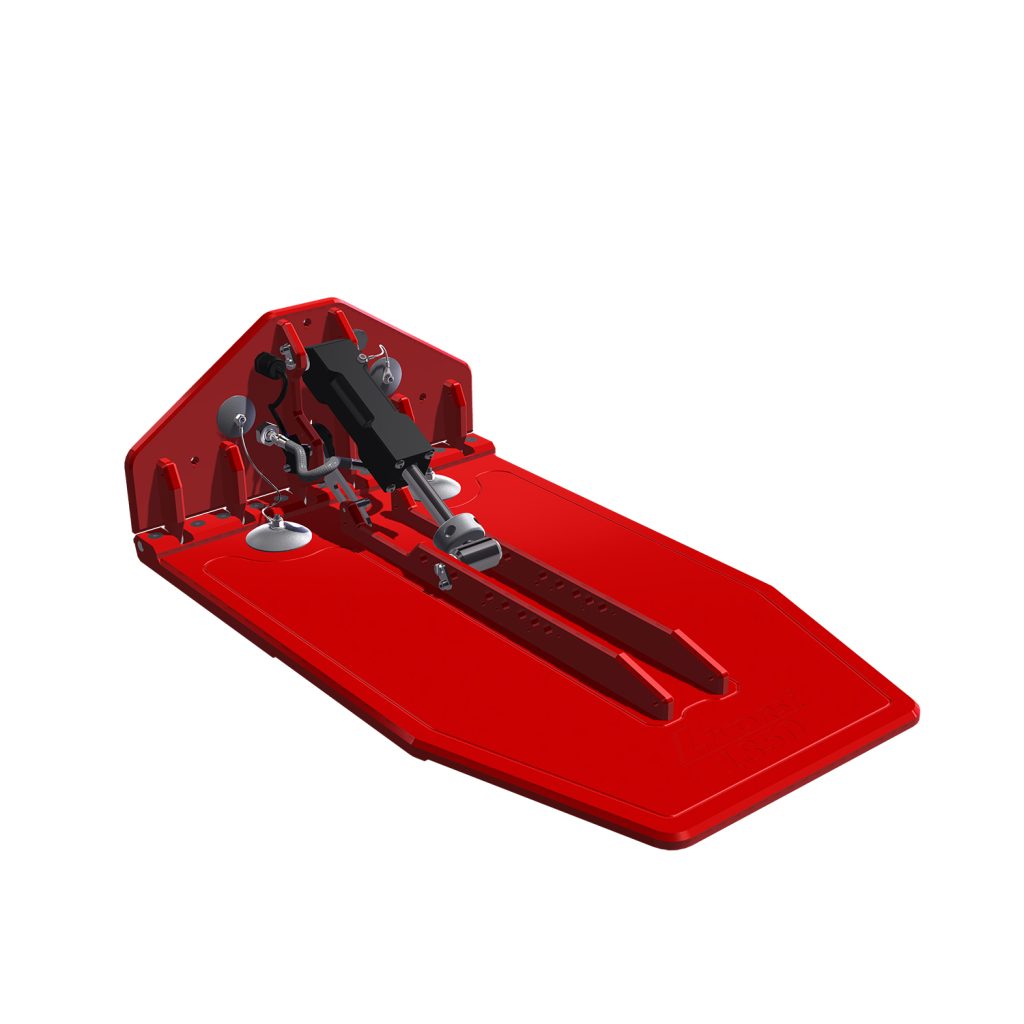

- Hydraulic trim tabs

- Docking and fender cleats

- Steering wheels

- Interior hardware like grab handles

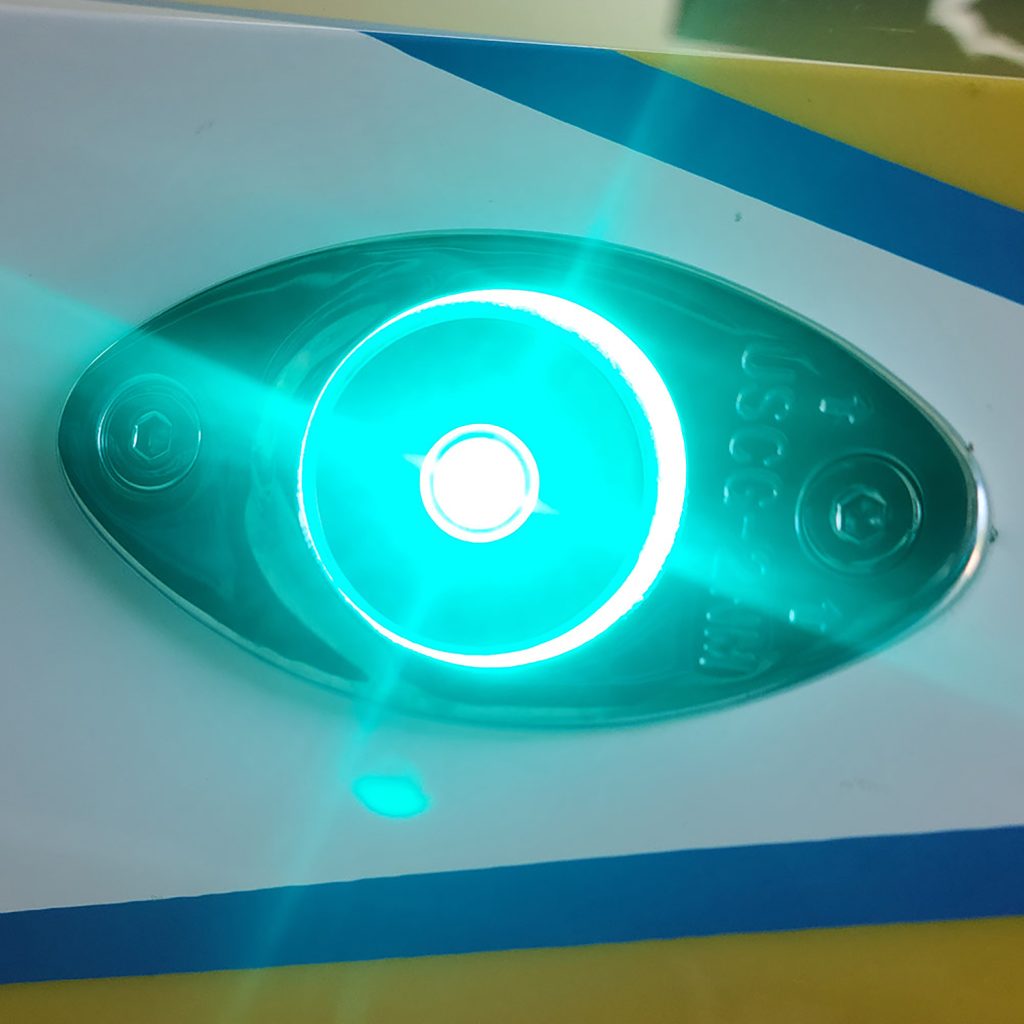

- LED lighting and electrical wire harnesses

- Custom boat ladders and more

Every product is designed with performance and reliability in mind.

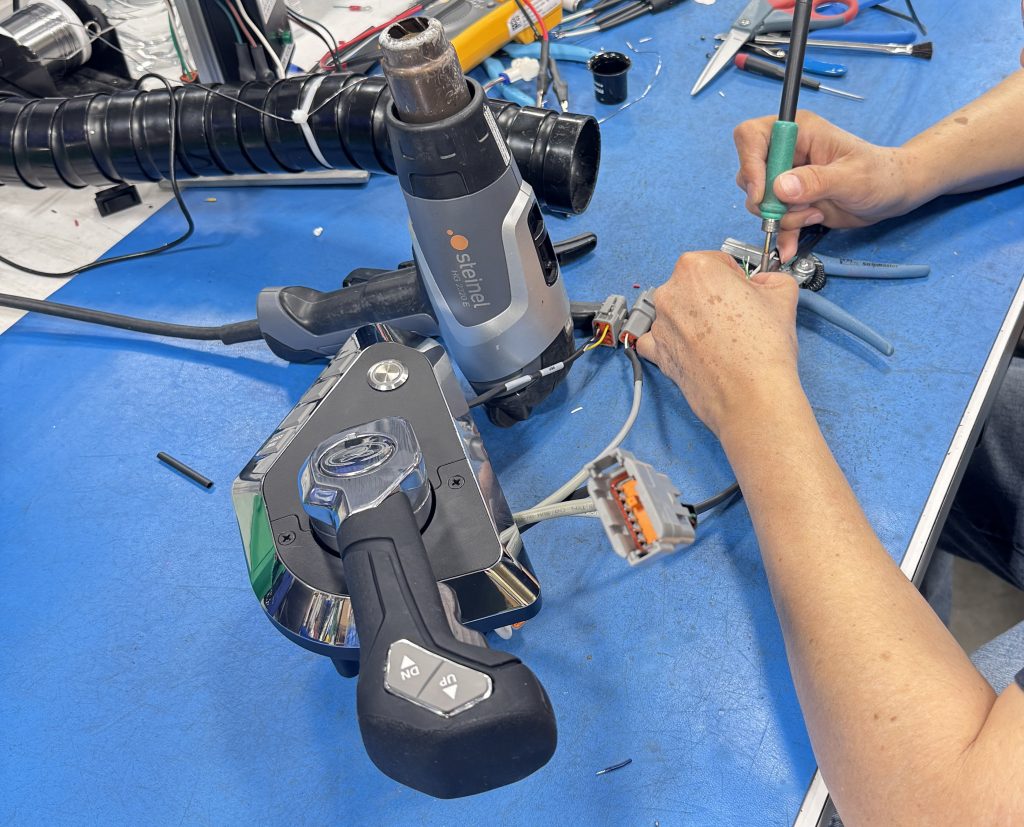

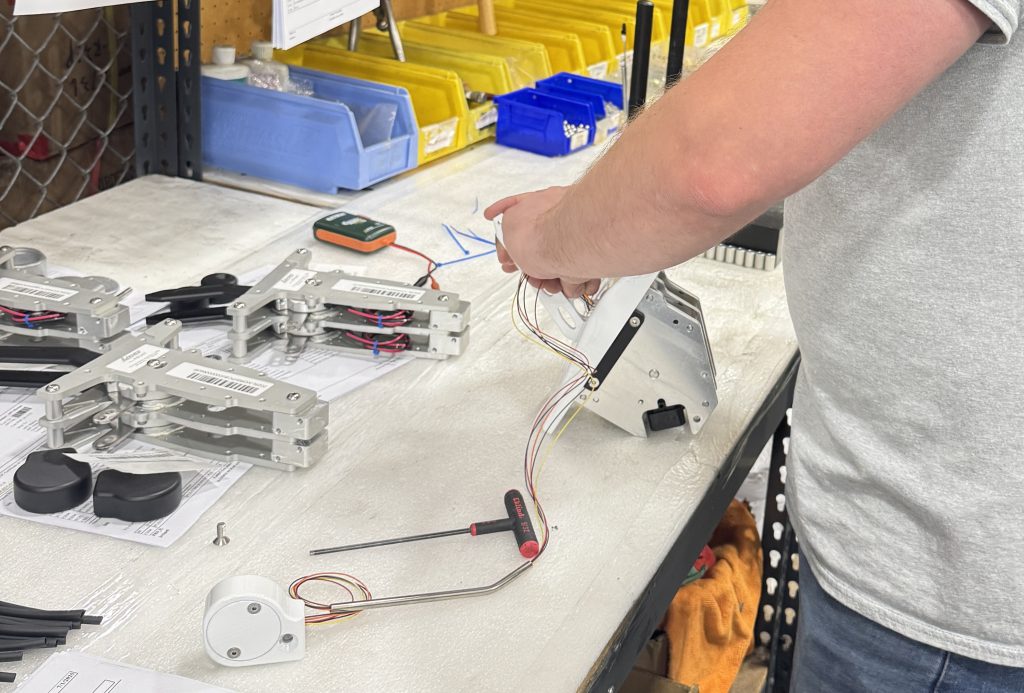

How We Build It

Livorsi does more than just assemble parts—we manufacture them. Inside our 150,000 sq. ft. facility in Grayslake, Illinois, our skilled team uses advanced tools like:

- CNC mills and Swiss-style lathes

- Laser and waterjet cutting machines

- Laser marking and direct-to-part printing

- Metal finishing, anodizing, and polishing

Our engineering team works closely with production to ensure everything meets high standards from design to final finish.

Testing for the Real World

We back up our quality with a full in-house test lab. Our dedicated quality engineers use:

- Hot/cold cycle chambers

- Vibration and pull testing

- Salt fog corrosion testing

- Optical scanning and CMM equipment

We push our parts to the limit so they’re ready for anything on the water.

Where We Operate

Our main facility is in Grayslake, IL, but we also manufacture parts in:

- Greenville, South Carolina (200,000 sq. ft.)

- Neenah, Wisconsin (100,000 sq. ft.)

Together, these locations help us keep production in-house and quality under control.

Markets Served

Tow Boats

Performance Boats

Military

Pleasure Boats